Introduction

The battle is frequently in the details in the field of industrial engineering and production. The effectiveness and durability of a product can be greatly impacted by its actually straightforward components. Industrial silicone wire seals are one example of these actually straightforward yet essential parts that are essential to maintaining the dependability and lifespan of electrical and electronic systems. We shall go into the realm of industrial silicone wire seals in this post, looking at its adaptability, uses, and benefits.

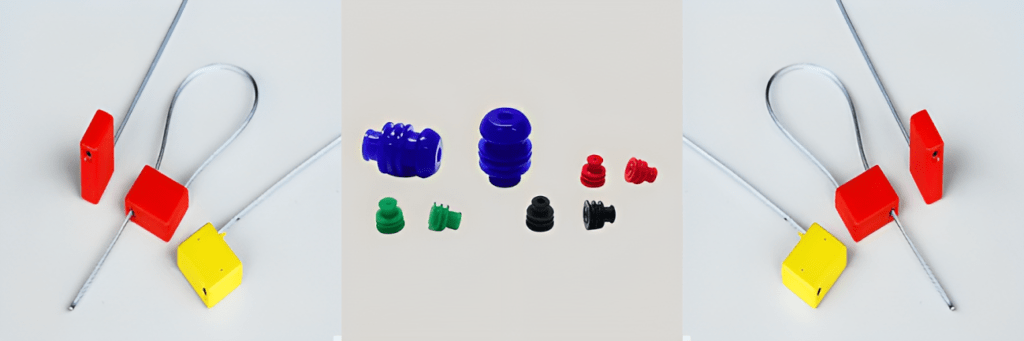

Understanding Silicone Wire Seals

Let’s start with the fundamentals before going further into the specifics. In harmful and industrial situations, silicone wire seals are safety tools used to insulate and seal electrical connections and wires. High-grade silicone rubber, used to create these seals, is renowned for its remarkable qualities, such as resistance to UV radiation, moisture, chemicals, and severe temperatures. As a result, silicone is the perfect material for sealing and safeguarding electrical connections, ensuring that they continue to function even under difficult circumstances.

Versatility in Applications

Silicone wire seals are widely used in the automobile industry to protect electrical connections in moving parts from moisture, particles, and temperature changes. Silicone wire seals are essential for preserving electrical integrity whether they are found in the engine compartment, underneath the dashboard, or inside the car.

Aerospace and Defense: Reliability is crucial in both defense and aerospace applications. In airplanes, military hardware, and satellites, delicate electronics and cables are safeguarded with silicone wire seals. They are extremely useful in these sectors because of their tolerance to high temperatures and severe chemicals.

Renewable Energy: Windmills and solar panels may function in a variety of weather scenarios. These systems’ electrical connections are shielded by silicone wire sealing, resulting in reliable operation and durability.

Industrial Automation: Silicone wire seals assist avoid electrical failures caused by moisture and dust infiltration in factories and industrial facilities where machinery and equipment are subjected to extreme circumstances.

Advantages of Industrial Silicone Wire Seals

Temperature Resistance: The outstanding temperature resistance of silicone wire seals is one of their most distinctive qualities. They are suited for usage in a variety of situations since they can tolerate high cold and heat.

Silicone rubber has a high level of resistance to chemicals, oils, and solvents. This characteristic guarantees that the seals endure exposure to caustic materials without breaking down.

Durability: Commercial silicone wire seals are made to withstand repeated use. They have an extremely long lifespan and may be exposed to external elements for long periods of time without degrading.

Simple Installation: These seals are frequently made to be simple to install, reducing downtime when doing maintenance or repairs.

Environmental Protection: Silicone wire seals are essential for keeping dangerous chemicals and liquids from leaking out of industrial machinery.

Although industrial silicone wire seals can appear to be minor parts, their importance cannot be emphasized. In a variety of sectors, they offer an essential layer of protection for electrical connections and cables, assuring the dependability and lifespan of crucial equipment. They are an unavoidable option for severe situations thanks to their outstanding temperature and chemical resistance and endurance. The adaptability of silicone wire seals will guarantee that they continue to play a significant role in protecting critical connections and electronics as industries continue to develop and place increasing demands on their electrical systems.