Introduction

Maintaining a secure and leak-free seal is crucial in the complex equipment and systems of modern industrial applications. Industrial bonded seals are essential when working with hydraulic systems, hydraulic machinery, or any other type of machinery where fluids or gases need to be limited. We’ll dig into the topic of industrial bonded seals in this post, learning what they are, how they function, and how important they are to many industries.

Industrial Bonded Seals

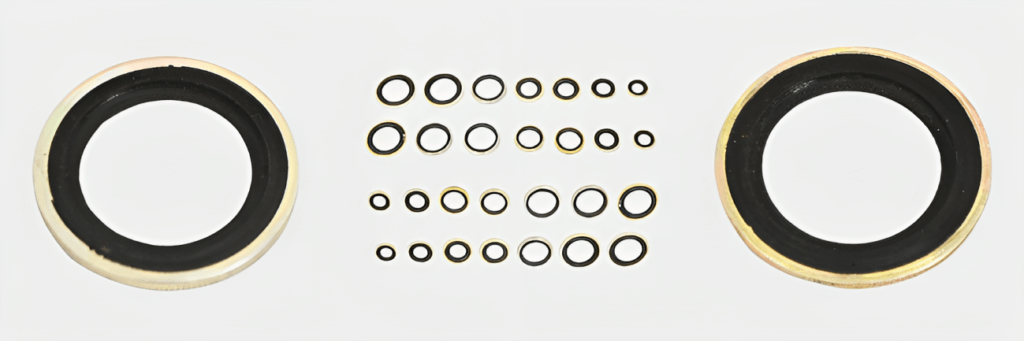

Industrial bonded seals are sealing components used to stop leaks in high-pressure connections. They are often referred to as Dowty seals or bonded washers. These seals have two primary parts: a metal washer and a flexible sealing element, which is commonly composed of silicone or rubber. A single, integrated unit is produced by bonding the washer and the sealing element.

How Do Industrial Bonded Seals Work?

Industrial bonded seals ability to work is a result of its clever design, which makes use of the benefits of both metal and rubber materials. Here is how they function:

Compression: A bonded seal is compressed between two surfaces when it is fitted in a fitting or connection. This compression causes the elastomeric sealing component to flex, sealing the two surfaces tightly.

flexibility: The elastomeric material’s natural flexibility enables it to adapt to a mating surface’s flaws or defects, creating a solid seal even under less-than-ideal circumstances.

Pressure Resistance: By providing stability and support, the metal washer aids in the seal’s capacity to tolerate high pressures without deforming or collapsing.

Leak Prevention: Industrial bonded seals are perfect for hydraulic, pneumatic, and other high-pressure systems because of the combination of compression, elasticity, and pressure resistance that assures they successfully prevent fluid or gas leaks.

Applications of Industrial Bonded Seals

Industrial bonded seals are used in a variety of sectors because of their adaptability and dependability. Among the frequent uses are:

In hydraulic fittings valves, and couplings, bonded seals are frequently used to stop oil or fluid leaks in high-pressure hydraulic systems.

Pneumatic Systems They keep airtight seals and prevent compressed air or gas leakage in pneumatic equipment and connections.

Bonded seals are employed in a variety of automobile applications, including fuel systems, stopping systems, and engine components.

Aerospace In vital hydraulic and pneumatic components of aircraft systems, bonded seals assist maintain a tight seal.

In the oil and gas sector where leaks can have serious effects on the environment and public safety, industrial bonded seals help to seal connections and joints.

Benefits of Industrial Bonded Seals

The use of industrial bonded seals offers several advantages:

Bonded seals are dependable in essential applications because of their long lifespan and acceptance to high pressures.

Cost-effective Bonded seals last a long time, requiring maintenance and replacements less frequently.

They are adaptable to a wide range of temperatures, fluids, and gases, making them appropriate for use in a variety of settings and industries.

Leak Prevention Their main duty is to stop leaks from happening, protecting the reliability and security of industrial systems.