Rubber Extruded Profiles in Pune

Table of Contents

Introduction

Puja Fluid Seals Pvt. Ltd. is a Industrial Rubber Products Manufacturer in India, it was founded in 1999 and has more than 30 years of domestic and international seals trading expertise. We collaborated with a number of well-known international manufacturers who hold market capital. Puja Fluid is AN ISO 9001:2015, ISO 14001:2015, ISO 45001:2018 and IATF 16949:2016 Certified Company. We provide a full selection of rubber products, including rubber extrusions, rubber bellows, rubber dust covers, rubber extruded products, hydraulic seals, pneumatic seals, diaphragms, anti-vibration mounts, and rubber moulded products. we are one of the best high quality rubber seals manufacturer.

Known as the “Oxford of the East” and a major hub for the manufacturing and automotive sectors, Pune is a city that is always a hive of invention. From large auto factories to complex machinery producers, there is a constant need for dependable, high-quality parts. Rubber extruded profiles, which provide unmatched performance and versatility across a wide range of applications, are a silent but essential part of these essential components. We are the best Rubber Extruded Profiles Manufacturer.

We at Puja Fluid Seals Pvt. Ltd. are aware of how crucial these profiles are. We are pleased to be a top producer and supplier of premium rubber extruded profiles in Pune, with more than 20 years of experience in the sealing sector and an accreditation. We are dedicated to offering solutions that improve your industrial operations’ lifespan, safety, and efficiency.

What Exactly Are Rubber Extruded Profiles

Consider passing a soft substance that resembles dough through a cookie cutter that has been carefully formed. That’s basically the idea behind extrusion of rubber! Rubber extrusion, to put it simply, is a manufacturing process in which raw rubber material natural or synthetic is heated before being pushed under intense pressure through a formed die. A continuous rubber length with a constant cross-sectional form is produced by this method.

Then, if necessary, these continuous lengths can be further processed and trimmed to the appropriate sizes.This process’s capacity to produce an amazing range of sizes and shapes is what makes it so beautiful. Rubber extrusion offers a high degree of customization, making it the perfect answer for a variety of industrial needs, from straightforward cords and strips to intricate custom designs.We are the best Rubber Extruded Profiles Supplier.

Why Choose Puja Fluid Seals Pvt. Ltd

When it comes to sourcing high-quality rubber extruded profiles in Pune, Puja Fluid Seals Pvt. Ltd. is a name that stands for excellence, reliability, and unparalleled expertise. With over of experience in sealing solutions, we have built a reputation as a trusted partner for businesses across various industries.

- Decades of Experience and Expertise: Puja Fluid Seals has been in the business of industrial rubber goods for more than having been founded in Time isn’t the only factor here; acquired knowledge, problem-solving skills, and a thorough comprehension of numerous industrial applications are also important. They have overcome obstacles, witnessed changes in the market, and continuously produced results.

- Vast Product Selection: Puja Fluid Seals offers more than just extruded profiles. They provide a wide range of rubber products, such as diaphragms, anti-vibration mounts, hydraulic and pneumatic seals, and rubber-molded goods. This makes your procurement process simpler because they may serve as a one-stop shop for many of your sealing and rubber component needs.

- Dedication to Quality: Puja Fluid Seals takes quality seriously. Their certifications include ISO 9001:2015, and This indicates that they follow strict international guidelines for automotive quality management systems, environmental management, occupational health and safety, and quality management. For you, this means dependable, consistent, and high-performing products.

- Advanced Manufacturing and Tooling: A well-equipped facility is necessary to produce high-precision extruded profiles. Puja Fluid Seals has made investments in a fully furnished modern tool room and cutting-edge manufacturing capabilities. This implies that they can precisely create unique dies and molds, guaranteeing that even intricate profiles satisfy your exact requirements.

- Technical Mastery and Personalization: Puja Fluid Seals has a highly skilled and knowledgeable staff. They are aware of the intricate technical details of extrusion procedures and rubber compounds. This enables them to design, develop, and choose the best materials for particular client needs and difficult applications in addition to manufacturing standard profiles. They have the know-how to meet any special needs you may have.

- Global Relationships and Competitive Pricing: Puja Fluid Seals is able to acquire raw materials effectively thanks to their global relationships with suppliers, which allows them to sell their products at competitive prices. In the price-conscious market of today, this is a huge benefit.

- Customer-Centric Approach: Long-standing clientele’ testimonials are very telling. Customers frequently emphasize Puja Fluid Seals’ dedication to customer satisfaction, timely delivery, zero rejections, and affordable costs. They see themselves as their clients’ partners, striving to deliver prompt services and technical assistance. Their operation is distinguished by its emphasis on establishing enduring partnerships.

- Innovation and Constant Improvement: The rubber sector is always changing, just like any other. Puja Fluid Seals is committed to continuously improving its methods and procedures because it understands this. They stay in the forefront of the market by continuously upgrading themselves to meet customer demands and the newest technological advancements.

Applications of Rubber Extruded Profiles

1. Automotive Industry

- Door Seals: To prevent dust, water, and sound from entering the vehicle.

- Window Channels: Helps glass move smoothly and seals the gap.

- Bonnet Seals: For protecting engine compartments from water and dust.

2. Construction and Infrastructure

- Window & Door Gaskets: Ensures proper sealing for soundproofing and weather resistance.

- Expansion Joint Seals: Used in bridges and buildings to absorb movement and vibration.

3. Electrical & Electronics

- Cable Management Seals: Protects electrical cables from environmental damage.

- Enclosure Gaskets: Provides sealing for control panels and electrical boxes.

4. HVAC and Refrigeration

- Used for air-tight sealing in HVAC ducts and refrigeration units to improve efficiency and prevent leakage.

5. Railway and Metro Coaches

- Profiles are used for door seals, window gaskets, and buffer pads to ensure safety and performance.

6. Marine & Aerospace

- Rubber profiles that can withstand salt water, high temperatures, and extreme pressure are used for sealing and vibration damping.

Pharmaceutical and Food Sector

- Silicone profiles are used in cleanroom applications and processing equipment due to their non-toxic and heat-resistant properties.

Specification Table of Rubber Extruded Profiles

| Parameter | Specification Range |

|---|---|

| Product | Rubber Extruded Profiles |

| Material Options | EPDM, Neoprene, Nitrile, Silicone, Natural |

| Hardness (Shore A) | 30 to 90 ± 5 |

| Temperature Range | -40°C to +250°C (material dependent) |

| Tensile Strength | > 7 MPa |

| Elongation | > 250% |

| Tolerance | As per IS/ASTM standards or custom |

| Color Options | Black, White, Red, Blue, Custom on request |

| Lengths Available | Coils or custom-cut lengths |

| Surface Finish | Smooth / Textured / Color Coated |

| Certifications | RoHS, FDA (for Silicone), ISO 9001:2015 |

Benefits of Rubber Extruded Profiles

- Outstanding Sealing Capabilities: This is arguably their most important and frequent application. In a variety of applications, rubber extruded profiles produce airtight and waterproof seals that stop liquid, gas, and even dust leaks. Consider window and door seals found on building facades, industrial gear, and automobiles.

- Rubber naturally absorbs shock and vibration, which helps to reduce noise and vibration. Extruded profiles are frequently used in machinery, automobiles, and structures to lessen vibrations, cushion impacts, and reduce noise, which promotes smoother operation and longer equipment life.

- Protection and Edge Trimming: They operate as protective covers for sharp edges on metal or glass, preventing injuries and shielding components from wear and tear. They are used as edge trims on doors, glass, and panels.

- Flexibility and Adaptability: Because rubber is naturally flexible, these profiles can adapt to uneven surfaces and allow for movement. They are therefore perfect for uses where components must flex or move without sacrificing protection or the seal.

- Durability and Longevity: Extruded profiles are resistant to abrasion, severe temperatures, chemicals, and UV rays when constructed from the proper rubber compounds. This results in less maintenance and a longer product lifespan.

- Cost-Effectiveness: The extrusion method is a cost-effective way to produce long, continuous lengths of rubber profiles, especially for high-volume manufacturing, because it is efficient and produces little waste.

- Personalization is essential: The ability to create almost any cross-sectional shape is one of the main benefits. This implies that companies can obtain a profile that is precisely customized to meet their unique requirements, guaranteeing a flawless fit and peak performance.

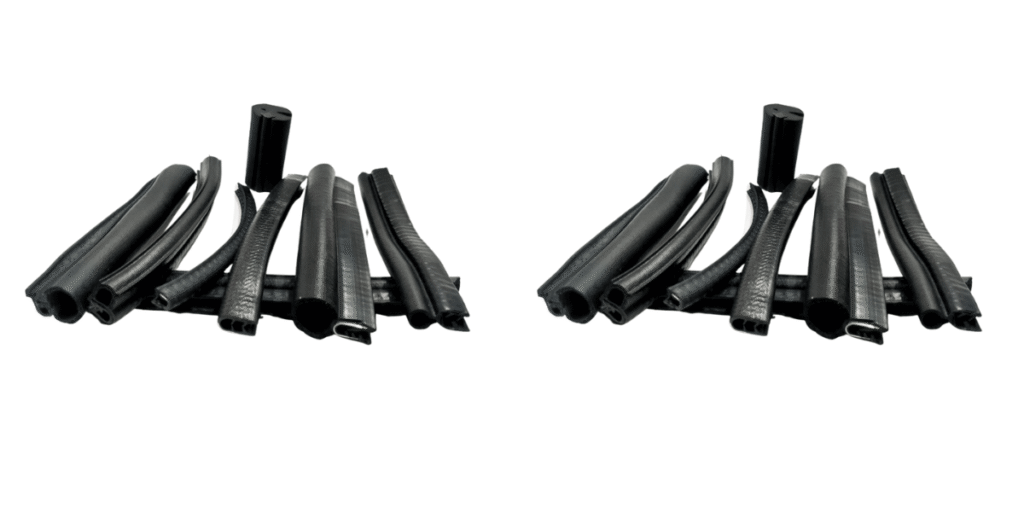

Types of Rubber Extruded Profiles

1. Rubber U Channel Profiles

- These are U-shaped profiles used to cover sharp metal edges or provide insulation. Commonly used in doors, hatches, and panels.

2. Rubber P Profiles

- P-shaped rubber profiles provide strong sealing properties and are used in automotive doors and industrial enclosures.

3. Rubber D Profiles

- D-profiles work as excellent weather strips and vibration dampers. Their flat base and rounded top provide effective sealing.

4. Rubber E Profiles

- E-seals are used in doors and windows for insulation and soundproofing. The design provides a tight grip and flexible sealing.

5. Rubber Lip Seals

- Lip seals help prevent dust, dirt, and moisture from entering enclosed spaces. Widely used in electrical cabinets and machinery covers.

6. Tubing and Sleeves

- These are hollow rubber tubes used to carry fluids or cover cables for insulation and protection.

7. Sponge Rubber Profiles

- Made from soft sponge rubber, these profiles are compressible and ideal for applications needing cushioning or air-tight sealing.

Conclusion

Although they are sometimes hidden, rubber extruded profiles are the unsung heroes of many industries. Numerous machinery and items run smoothly and effectively because to their capacity to cushion, seal, and protect. The need for these adaptable parts is rising in a bustling industrial center like Pune, which encourages manufacturers to innovate.

Businesses in Pune and beyond looking for dependable, superior, and bespoke rubber extruded profiles can turn to Puja Fluid Seals Pvt. Ltd. because of its extensive capabilities, track record, and steadfast dedication to quality. Join together with us to guarantee that your applications take use of the most advanced fluid sealing technology.