Oil Seals Pune

Introduction

Established in 1999, Puja Fluid sealing Pvt. Ltd. is an Indian manufacturer of industrial rubber products with over 30 years of experience in both domestic and international sealing business. A number of well-known global manufacturers with market capital worked with us. The ISO 9001:2015, ISO 14001:2015, ISO 45001:2018, and IATF 16949:2016 certifications have all been earned by Puja Fluid. We offer a wide range of rubber products, such as diaphragms, anti-vibration mounts, rubber extrusions, rubber bellows, rubber dust covers, rubber extruded products, hydraulic seals, and pneumatic seals. We are among the top producers of premium rubber seals.

Pune is a shining example of manufacturing excellence at the center of India’s industrial landscape. Oil seals, one of its numerous industrial components, are essential to the reliable and effective operation of machinery. These crucial elements protect the longevity and functionality of equipment by halting oil leaks and the entry of impurities.

Puja Fluid Seals Pvt. Ltd. is a leading oil seal manufacturer in Pune that is well-known for its dedication to excellence, creativity, and client satisfaction. Puja Fluid Seals has built a solid reputation as a reliable partner for businesses in India and abroad because to its extensive product line and decades of experience.

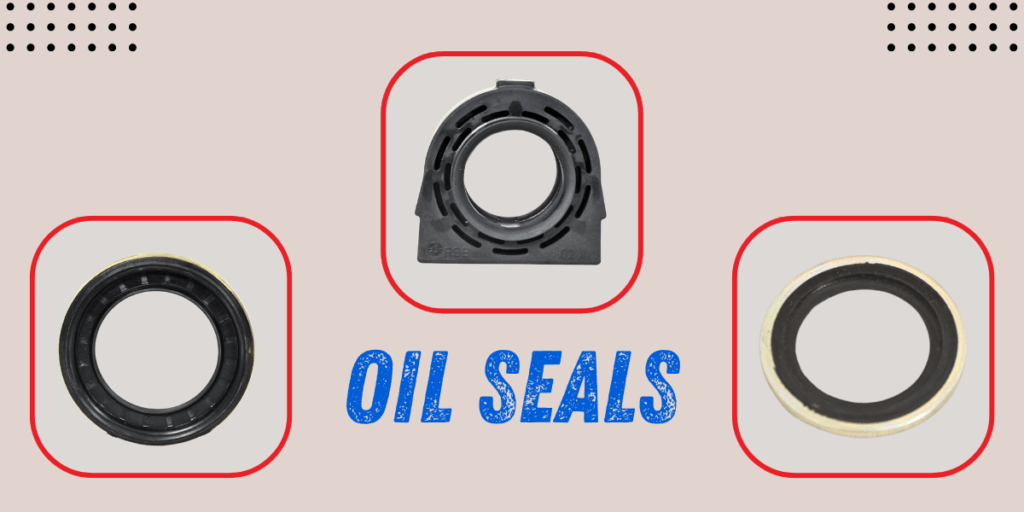

What Are Oil Seals?

Oil seals, sometimes referred to as radial lip seals or rotary shaft seals, are mechanical elements used in machinery to close up the gaps between moving and stationary parts. Their main purpose is to keep lubricants in the system while blocking the passage of outside impurities including moisture, dust, and grime. This dual action prolongs the life of equipment, minimizes downtime, and guarantees the smooth operation of machinery. We are the best Oil Seals.

Why Choose Oil Seals Pune

- Vast Experience: We offer decades of fluid sealing technology industry experience.

- Quality Assurance: To ensure that our products meet international standards, they undergo stringent quality testing.

- Custom Solutions: We are experts at modifying seals to meet your particular operational needs.

- Competitive Pricing: High quality at a lower price.

- Prompt Delivery: A dependable and quick supply chain will guarantee that your operations have as little downtime as possible.

- Technical Support: Our engineers are available at all times to assist you in selecting and putting the appropriate seal in place.

When you choose Puja Fluid Seals Pvt. Ltd., you’re choosing dependability, performance, and a dedication to quality. We are the best Oil Seal Supplier.

Applications of Oil Seals

Oil seals from Puja Fluid Seals Pvt. Ltd. are essential in a wide range of sectors and applications due to their superior quality and adaptability. Our seals are essential in the following important sectors:

- Automobile Sector:

- Engines: To stop oil leaks and safeguard important rotating parts, crankshaft, camshaft, valve stem, and accessory drive seals are used.

- Manual and automatic transmissions: smooth gear shifts and effective power transfer are ensured by input shaft seals, output shaft seals, and other internal seals that preserve fluid integrity and stop lubricant loss.

- Axles and Differentials: To stop leaks and contamination, axle shaft and pinion seals keep gear oil inside the axle housing.

- Wheel Hubs: Wheel bearing seals, which are frequently sturdy cassette seals, keep grease in place while shielding wheel bearings from impurities, water, and dirt.

- Power Steering Systems: Leakage of hydraulic fluid is prevented by seals in the steering rack and power steering pump.

- Suspension Systems: For efficient damping, hydraulic fluid pressure is maintained by seals in shock absorbers and struts.

- Fluid Power Systems: Pneumatics and Hydraulics

- Hydraulic Cylinders: In order to maintain system pressure, stop internal and exterior leaks, and keep impurities out, rod, piston, and wiper seals are essential. Construction machinery, agricultural equipment, industrial presses, and earthmoving equipment all require our hydraulic seals.

- Hydraulic motors and pumps: Shaft seals, which are frequently rated for high pressure, stop hydraulic fluid from escaping from the motor shaft or pump.

- Pneumatic Cylinders and Valves: In pneumatic systems, rod and piston seals guarantee effective air pressure containment and stop leaks.

- Manufacturing & Industrial Machinery:

- Gearboxes and Reducers: In industrial gearboxes used in conveyors, machine tools, and heavy machinery, input and output shaft seals are crucial for keeping lubricating oil contained and safeguarding gears and bearings.

- Electric motors: Seals on the motor shaft shield internal windings from ambient pollutants and stop grease from leaking from bearings.

- Pumps: Shaft seals shield internal parts from abrasive media and stop fluid leakage in centrifugal, positive displacement, and vacuum pumps.

- Compressors: To maintain pressure, avoid lubricant contamination, and guarantee effective operation, seals are essential in air and gas compressors.

- Machine Tools: Seals that shield delicate parts from coolant, chips, and lubricants are present in spindles, chucks, and lead screws.

- Conveyor Systems: In damp or dusty conditions, seals on idlers and rollers guard against bearing contamination.

- Equipment for Earthmoving and Agriculture:

- Excavators, loaders, harvesters, and tractors: These powerful devices work in challenging conditions. Axles, transmissions, wheel hubs, hydraulic cylinders, and engine parts all require our durable oil seals to endure mud, water, filth, and extremely high or low temperatures. Here, cassette seals are especially well-liked. We are the best Oil Seal Provider

- Process Industries (Food and Beverage, Pharmaceutical, Petrochemical, and Chemical):

- Seals are essential: for keeping different chemicals, slurries, and food items contained while avoiding contamination in pumps and agitators. Here, material compatibility (such as FKM and PTFE) is crucial.

- Reactors and mixers: Seals on revolving shafts keep things hygienic or stop dangerous materials from escaping.

- Conveyor and Material Handling Systems: Seals shield processing equipment bearings from harsh chemicals and temperatures.

6. Generation of Power:

- Steam and gas turbines: Lubrication systems and auxiliary equipment seals guarantee effective operation and stop oil leaks.Generators: Seals stop lubricant migration and safeguard bearings.

- Utilities and General Engineering:

- Fans and Blowers: Shaft seals stop bearings from leaking oil.

- Washing machines and household appliances: Water and detergent containment is guaranteed via seals in motors and drum assemblies.

- Railway Applications: Seals in gearboxes, brake systems, and other bogie components.

- Textile Machinery: Lubrication is maintained while lint and dust infiltration is prevented by seals in spindles, rollers, and other spinning components.

- Water Treatment Plants: Water and different chemicals are handled by seals in pumps and agitators.

Types of Oil Seals

A large variety of oil seal types, each designed for certain working circumstances, pressure ratings, and contamination levels, are required due to the variety of industrial uses. A wide variety of these seals are produced and supplied by Puja Fluid Seals Pvt. Ltd., which uses its experience to offer the best solutions.

- Single Lip Seals: Simple style for all-purpose use.

- Double Lip Seals: An extra lip to manage the removal of debris

- Cassette Seals: Incorporated parts for demanding uses

- V-Ring Seals: Rotating shaft axial seals

- Labyrinth Seals: Low-wear, non-contact seals

Materials Used in Oil Seals

Performance, thermal resistance, and chemical compatibility are all impacted by the material selection:

- Nitrile Rubber (NBR): Economical and appropriate for the majority of uses.

- Fluorocarbon (Viton®): Superior resistance to chemicals and high temperatures.

- Silicone: Excellent in extremely hot or cold temperatures.

- Polyacrylate (ACM): Excellent grease and heat resistance.

- Teflon® (PTFE): Excellent chemical resistance and minimal friction.

How to Select the Right Oil Seal

Selecting the appropriate oil seal requires taking into account a number of factors:

- Dimensions of the shaft and bore.

- Temperature of operation

- Speed of rotation

- Conditions of the environment (dust, chemicals, moisture)

- Type of lubricant

Making the right choice extends machine life, minimizes downtime, and guarantees ideal sealing.

Conclusion

Oil seals play a quiet but crucial part in the complex dance of machinery. Operational effectiveness, longer equipment lifespan, less downtime, and significant cost savings are all strongly correlated with their quality. Puja Fluid Seals Pvt. Ltd. is a monument to manufacturing excellence in the fluid sealing business in Pune, a city known for its industrial progress and innovation.

Puja Fluid Seals Pvt. Ltd. is in a unique position to meet and surpass your sealing needs thanks to its more than 20 years of experience, extensive product range made from the best materials, extensive suite of ISO and IATF certifications, and unwavering, demonstrated commitment to customer satisfaction. We are a devoted partner who is committed to improving the functionality, durability, and profitability of your equipment—we are more than just a provider.