Industrial Silicone Rubber Tubings

Table of Contents

Introduction

Puja Fluid Seals Pvt. Ltd. is a Industrial Rubber Products Manufacturer in India, it was founded in 1999 and has more than 30 years of domestic and international seals trading expertise. We collaborated with a number of well-known international manufacturers who hold market capital. Puja Fluid is AN ISO 9001:2015, ISO 14001:2015, ISO 45001:2018 and IATF 16949:2016 Certified Company. We provide a full selection of rubber products, including rubber extrusions, rubber bellows, rubber dust covers, rubber extruded products, hydraulic seals, pneumatic seals, diaphragms, anti-vibration mounts, and rubber moulded products. we are one of the best high quality rubber seals manufacturer. We are the best silicone rubber tubings manufacturer.

Industrial silicone rubber tubings’ adaptability, toughness, and exceptional performance in demanding environments have made them a crucial part of many different sectors. Silicone tubing is essential for applications needing flexibility, resilience to high temperatures, and chemical compatibility in the food & beverage, medical equipment, aerospace, and automotive sectors. We will examine the characteristics, advantages, uses, and reasons Puja Fluid Seals Pvt. Ltd. is the best partner for premium silicone rubber tubings in this extensive post.

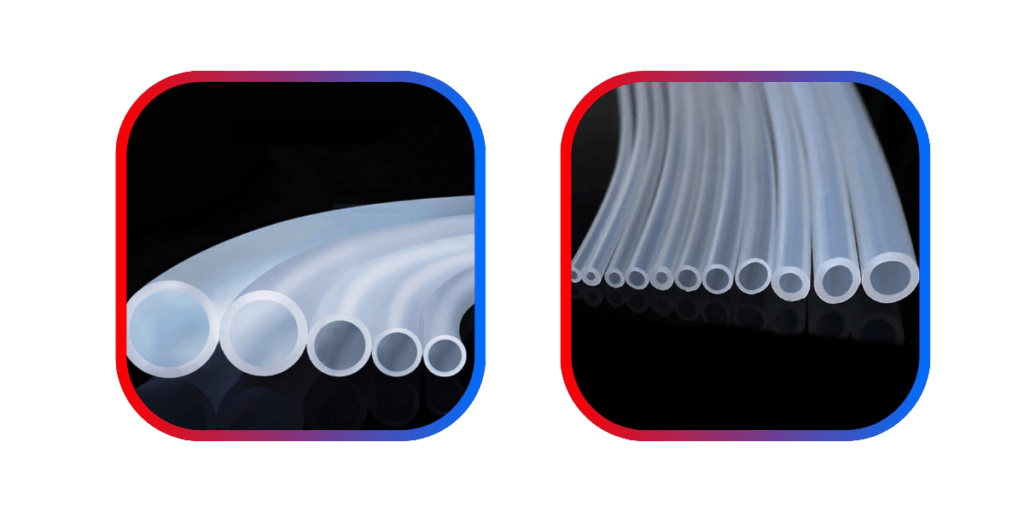

What are Industrial Silicone Rubber Tubings?

Flexible piping composed of silicone elastomers is known as silicone rubber tubing. These tubings are well known for their remarkable qualities, which include:

- Temperature Resistance: They can tolerate temperatures ranging from -60°C to 200°C, which makes them appropriate for both frigid and extremely hot environments.

- Flexibility: Maintains adaptability even in harsh circumstances, guaranteeing user-friendliness in intricate configurations.

- Durability: Longer lifespan than other materials due to resistance to ageing, ripping, and cracking.

- Chemical Resistance: Able to withstand a variety of chemical exposures without deteriorating.

- Non-Toxic: Adhering to industry standards such as FDA, USP Class VI, and ISO certifications, it is safe for use in food-grade and medical applications.

Key Benefits of Silicone Rubber Tubings

- Long Life

Because of their exceptional resistance to deterioration, silicone tubings are an affordable option for businesses. - Adaptability

They serve a range of purposes, including low-temperature settings and high-pressure applications. - Sterilisation Ease

These tubings are perfect for the pharmaceutical and medical industries since they can be sterilised repeatedly without losing their integrity. - Environmentally Friendly

Compared to many alternatives, silicone tubings have a smaller environmental impact because they are made of recyclable materials. - Personalisation Choices

To satisfy certain industrial needs, they are offered in a range of sizes, colours, and hardness levels.

Types of Industrial Silicone Rubber Tubings

- Silicone tubing at high temperatures

utilised in parts for automobiles, heating systems, and ovens that must be exposed to high temperatures. - Silicone Tubing of Food Grade

This tubing is safe to use in food and beverage applications because it is manufactured in accordance with FDA regulations, guaranteeing no contamination. - Silicone tubing of medical quality

frequently utilised in healthcare for medical devices, catheters, and surgical instruments. It can be sterilised and is biocompatible. - Tubing made with reinforced silicone

Frequently seen in industrial machinery and hydraulic systems, these devices are made with extra layers to increase their resistance to pressure. - Silicone tubing that is transparent

makes the fluid flow visible, which is perfect for applications requiring monitoring.

Advantages of Industrial Silicone Rubber Tubings

- Adaptability

Applications for silicone tubings are numerous and include everything from delicate medical equipment to industrial gear. - A remarkable range of temperatures

Silicone tubings, in contrast to other materials, maintain their strength and flexibility throughout a wide temperature range. - Contamination Resistance

Silicone is perfect for hygienic applications since it inhibits the formation of microorganisms. - Compact

Silicone tubings are lightweight despite their durability, which makes installation simpler and less taxing on the equipment they are linked to. - Economicalness

Long-term cost reductions are offered by silicone tubings because of their resilience and ease of maintenance.

Applications of Industrial Silicone Rubber Tubings

- The Food and Drink Sector

Because they are non-toxic, they are utilised in dairy processing, beverage lines, and dispensing devices. - The Medical and Pharmaceutical Sector

vital for laboratory apparatus, fluid transport, and medication delivery systems. - Automobile Sector

Because of their resilience to heat and chemicals, they are utilised in fuel systems, coolant hoses, and vacuum lines. - The Aviation Sector

Perfect for applications involving high temperatures, guaranteeing dependability under harsh circumstances. - Equipment for Industry

frequently utilised in conveying systems, hydraulic systems, and sealing applications. - The Electrical Sector

preferred for electrical wiring insulation and protective coatings.

Why Choose Puja Fluid Seals Pvt. Ltd. for Your Silicone Rubber Tubing Needs?

We at Puja Fluid Seals Pvt. Ltd. take great satisfaction in providing the best silicone rubber tubings that are suited to a variety of industrial needs. Here’s why we’re the preferred vendor:

- Outstanding Quality

Premium-grade materials are used in the production of our silicone tubings to guarantee its dependability, flexibility, and durability. - Personalisation Choices

To meet your specific demands, we offer tubing solutions in a range of sizes, thicknesses, and specifications. - Adherence to the Standards

Our products are safe and high-quality since they meet industry standards such as FDA, ISO, and RoHS. - Reasonably priced

We provide affordable solutions without sacrificing quality. - Professional Assistance

Our knowledgeable staff is available at all times to help you choose the ideal tubing for your needs. - A Vast Selection of Items

We provide a wide variety of industrial rubber products in addition to silicone tubings.

How to Select the Right Silicone Rubber Tubing?

A number of things need to be taken into account while selecting silicone rubber tubing for your application:

- Application Requirements: Determine the environment and purpose of the tubing’s use.

- Range of Temperature: Verify that the tubing can tolerate the operating temperature.

- Verify chemical compatibility with the gases or fluids that are going through.

- Pressure Tolerance: If the application calls for high pressure, choose reinforced tubing.

- Regulatory Compliance: Check to see whether the tube satisfies the necessary industry requirements.

Conclusion

Industrial silicone rubber tubings, which provide unparalleled performance, durability, and flexibility, are a crucial component in many different sectors. They are a dependable option for a variety of applications due to their capacity to tolerate harsh environments and adhere to strict safety regulations. We are the best silicone rubber tubings supplier.

Puja Fluid Seals Pvt. Ltd. is a reputable brand in the business for locating premium silicone rubber tubings. Our dedication to quality, personalisation, and client pleasure guarantees that our products will both meet and beyond your expectations.To find out more about our silicone rubber tubing options and how we can help you meet your industrial demands, get in touch with us right now.