Hydraulic Seals Manufacturer

Table of Contents

Introduction

Puja Fluid Seals Pvt. Ltd. is a Industrial Rubber Products Manufacturer in India, it was founded in 1999 and has more than 30 years of domestic and international seals trading expertise. We collaborated with a number of well-known international manufacturers who hold market capital. Puja Fluid is AN ISO 9001:2015, ISO 14001:2015, ISO 45001:2018 and IATF 16949:2016 Certified Company. We provide a full selection of rubber products, including rubber extrusions, rubber bellows, rubber dust covers, rubber extruded products, hydraulic seals, pneumatic seals, diaphragms, anti-vibration mounts, and rubber moulded products. we are one of the best high quality rubber seals manufacturer.

The foundation of contemporary industries is hydraulic systems. Hydraulic technology powers machinery with efficiency and accuracy in a variety of fields, including heavy engineering, aerospace, and agriculture. Hydraulic seals, the unsung heroes that guarantee dependable, leak-free, and seamless operation, are at the core of these systems.Look no further if you’re trying to find a reliable manufacturer of hydraulic seals. Your dependable partner, Puja Fluid Seals Pvt. Ltd., offers premium sealing solutions made to improve hydraulic equipment performance, decrease downtime, and increase equipment longevity. We are the best Hydraulic Seals Supplier.

What Are Hydraulic Seals

Hydraulic seals are specialized components used in hydraulic cylinders. Their main role is to prevent fluid leakage, maintain pressure, and keep contaminants out of the system. By ensuring a tight seal between different cylinder parts, hydraulic seals help machines perform their functions with maximum efficiency.Hydraulic systems would have issues including fluid leaks, pressure loss, contamination, and equipment failure in the absence of high-quality seals. Selecting a trustworthy hydraulic seals manufacturer is crucial for this reason. We are the best Hydraulic Seals Provider.

Why Choose Puja Fluid Seals Pvt. Ltd

- Unmatched Expertise: Our group of passionate and highly skilled experts is committed to comprehending your particular requirements. We offer useful answers to challenging sealing issues in addition to selling seals. You will always receive the correct product thanks to our in depth knowledge and vast application experience.

- Large Product Selection: We have one of the largest assortments of hydraulic and pneumatic seals on the market, including chevron packing, wiper seals, piston seals, rod seals, and more. From precision machine tools to heavy-duty earth-moving equipment, our extensive collection guarantees that we have the ideal seal for your particular application.

- Complete Quality Commitment: By emphasizing timely delivery, continuous improvement, and customer satisfaction, we hope to become one of India’s top manufacturers and suppliers. We are committed to fostering a culture of excellence in order to create profitable, enduring partnerships with our clients.

- Expertise and expertise: Our team has years of expertise in the field and is well-versed in hydraulic systems and the unique difficulties they encounter. We can assist you in selecting the ideal seal for your need, guaranteeing lifetime and peak performance. We offer solutions in addition to seals.

- Superior Raw Materials: We always utilize the greatest raw materials from reliable vendors. Our seals are produced with cutting-edge methods and long-lasting materials such premium polyurethane guaranteeing their resistance to harsh environmental factors pressure and temperature.

- Innovation and Customization: We are aware that each hydraulic system is distinct. For this reason, we provide a large selection of standard seals in addition to our expertise in tailored solutions. Our staff can create and produce a seal that precisely matches your specifications, regardless of whether you require a particular size, shape, or substance for a special purpose.

- Strict Quality Control: A rigorous quality control procedure is applied to each seal before it leaves our facility. To make sure our goods live up to the highest performance and durability standards, we test them. Our seals always fit perfectly and operate without leaking because to our dedication to quality.

- Customer-Centric Approach: Our clients come first at Puja Fluid Seals Pvt. Ltd. We offer first-rate client care, from the first consultation to post-purchase assistance. Our staff is available at all times to respond to your inquiries and offer technical support.

Applications of Hydraulic Seals

1. Construction Industry

- Hydraulic cylinders are widely used in construction equipment like excavators, bulldozers, cranes, and loaders. Hydraulic seals ensure that these machines operate under high loads without leakage.

2. Agriculture and Farming

- Modern tractors, harvesters, and irrigation systems rely heavily on hydraulics. Our seals help maintain smooth functioning of agricultural machinery, leading to better productivity in farming.

3. Automobile and Transport

- Hydraulic systems are found in brakes, clutches, and shock absorbers of vehicles. Strong and durable hydraulic seals are critical for safety and efficiency in automobiles.

4. Aerospace Industry

- Aircraft hydraulic systems use seals in landing gears, flight controls, and cargo doors. These applications demand seals that can withstand extreme conditions, which Puja Fluid Seals Pvt. Ltd. specializes in manufacturing.

5. Manufacturing and Industrial Machinery

- Hydraulic presses, injection molding machines, and material handling equipment use seals to maintain smooth operation and avoid breakdowns.

6. Mining and Heavy Equipment

- Mining machinery works in harsh environments with dust, mud, and heavy pressure. Our seals ensure reliable performance in these challenging conditions.

7. Oil & Gas Industry

- Drilling equipment and offshore machinery depend on hydraulic seals to handle high pressures and corrosive environments.

Table Specifications of Hydraulic Seals

| Specification | Details |

|---|---|

| Material Used | Hydraulic Seals |

| Operating Temperature | -40°C to +200°C (depending on material) |

| Pressure Range | Up to 700 bar |

| Speed Capability | Up to 15 m/s |

| Hardness (Shore A) | 70 – 95 |

| Applications | Hydraulic cylinders, presses, injection molding machines, heavy equipment |

| Customization | Available as per client’s requirement |

| Sizes | Standard & non-standard (custom sizes available) |

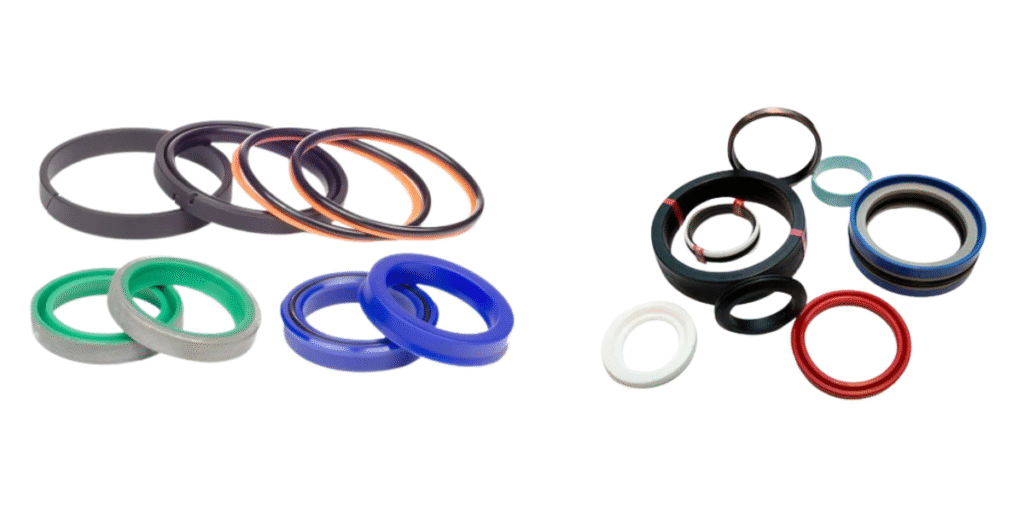

| Color Options | Black, Blue, Green, Brown (custom colors available) |

Advantages of Hydraulic Seals

- Increased Efficiency: Better, more reliable seals are produced by high-quality seals. This results in a more steady pressure, less fluid bypass, and a more effective power transfer. Your equipment consumes less energy and operates more quickly.

- Extended Equipment Life: A hydraulic system’s worst enemies are pollution and leaks. The inside surfaces of the cylinder can sustain severe wear and tear from a little particle of dirt or grit that passes through a wiper seal. High-quality seals, particularly wiper seals, offer an efficient barrier that prolongs the life of your machinery and protects your costly components.

- Decreased Maintenance Costs and Downtime: Your equipment stops functioning when a seal fails. Emergency repairs and expensive downtime result from this. You may drastically lower the frequency of maintenance and prevent unforeseen disruptions by choosing strong, long-lasting seals.

- Enhanced Safety: In applications like cranes or lifts, where a rapid drop could be disastrous, a sudden loss of pressure brought on by a seal failure can pose a serious safety risk. High-quality seals provide dependable system operation, safeguarding both the apparatus and its users.

- Resistance to Adversities: High temperatures, hostile fluids, and abrasive particles can make the operating environment for hydraulic seals harsh. High-quality seals are made from cutting-edge materials that can resist these harsh circumstances without deteriorating, such as premium polyurethane or specifically blended rubber.

- Increases Equipment Life and Prevents Leaks: The best protection against fluid leaks, which can result in pressure loss, system inefficiency, and harm to nearby components, is a strong seal. The lifespan of your gear is greatly increased by high-quality seals, which keep pollutants out and the hydraulic fluid confined.

- Minimizes Maintenance and Downtime: Costly downtime and frequent repairs are the results of frequent seal failures. You may lower the need for maintenance and maintain the efficiency of your business by purchasing long-lasting seals from a reputable manufacturer.

- Boosts Efficiency and Safety: Leaking hydraulic systems can present safety hazards and hazardous conditions. Superior seals guarantee the system runs effectively and safely while preserving the pressure required for optimal performance.

Types of Hydraulic Seals

1. O-Ring Seals

- O-rings are one of the most popular hydraulic seals due to their simple design and excellent sealing capability. They are typically made from rubber or synthetic materials and fit into grooves to prevent fluid leakage. O-rings are versatile, cost-effective, and suitable for both static and dynamic applications.

2. Rod Seals

- Rod seals are used to prevent fluid leakage along the rod of a hydraulic cylinder. They are designed to withstand high pressures and ensure smooth movement of the rod. These seals are commonly found in applications like construction machinery, manufacturing equipment, and automotive systems.

3. Piston Seals

- Piston seals prevent hydraulic fluid from passing between the piston and cylinder bore, maintaining the efficiency of the cylinder. These seals are critical for ensuring that hydraulic cylinders operate with precision and consistency.

4. Wiper Seals Scraper Seals

- Wiper seals are placed at the rod end of a cylinder to prevent dust, dirt, and other contaminants from entering the hydraulic system. By keeping the system clean, wiper seals reduce wear and tear on other components and improve overall performance.

5. U-Cup Seals

- U-cup seals are named for their U shaped cross-section, which helps them provide excellent sealing under high pressure. These seals are widely used in dynamic applications where the piston or rod moves frequently.

6. Back-Up Rings

- Back-up rings are used in combination with other seals to prevent extrusion under high pressure. They reinforce primary seals and extend the life of the hydraulic system.

Conclusion

In the rigorous realm of industry, dependability is crucial. A machine’s performance can be made or broken by its smallest part. You can make sure your operations continue to function smoothly and effectively for many years to come by cooperating with a reliable manufacturer and realizing the crucial role hydraulic seals play. We are the Best Hydraulic Seals Manufacturer.

Our goal at Puja Fluid Seals Pvt. Ltd. is straightforward: to offer affordable, tailored solutions with unparalleled support and service. As a devoted sealing specialist, we take pride in our dedication to excellence and client satisfaction.