Bonded Seals Supplier in Pune

Table of Contents

Introduction

Puja Fluid Seals Pvt. Ltd. is a Industrial Rubber Products Manufacturer in India, it was founded in 1999 and has more than 30 years of domestic and international seals trading expertise. We collaborated with a number of well-known international manufacturers who hold market capital. Puja Fluid is AN ISO 9001:2015, ISO 14001:2015, ISO 45001:2018 and IATF 16949:2016 Certified Company. We provide a full selection of rubber products, including rubber extrusions, rubber bellows, rubber dust covers, rubber extruded products, hydraulic seals, pneumatic seals, diaphragms, anti-vibration mounts, and rubber moulded products. we are one of the best high quality rubber seals manufacturer.

In the bustling industrial landscape of Pune, where precision engineering and manufacturing thrive, the importance of reliable components cannot be overstated. Among the myriad of parts that ensure the smooth and safe operation of machinery, seals play a critical, though often unseen, role. In the world of fluid power and engineering, a specific type of seal has earned a reputation for its reliability and robust performance: the bonded seal.

This article delves into the world of seals, exploring their function, benefits, and applications. We will also shine a light on why, as a seals supplier in Pune, Puja Fluid Seals Pvt. Ltd. stands out as the ideal partner for your sealing needs, offering unparalleled quality, expertise, and customer service.We are the best Bonded Seals Manufacturer.

What Exactly is a Bonded Seal

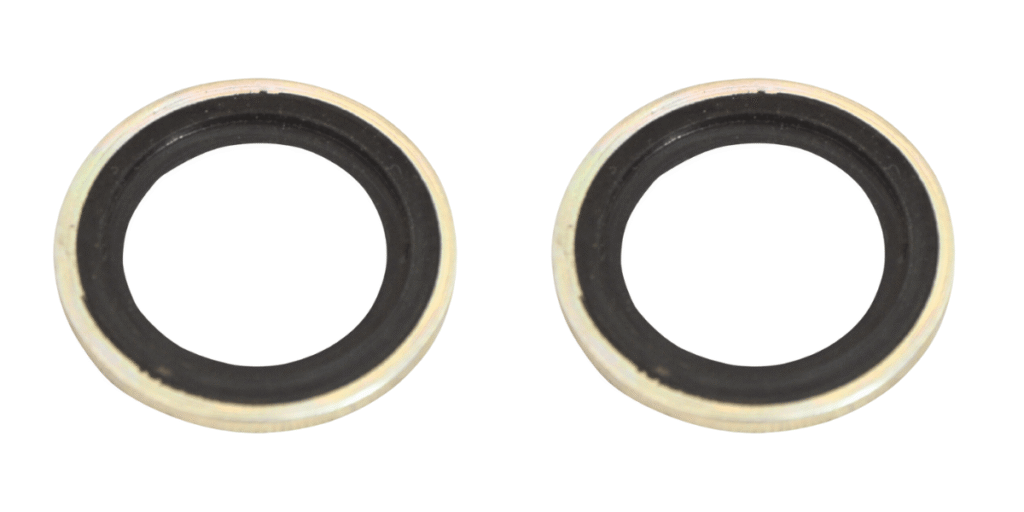

At its core, a bonded seal is an ingenious combination of two materials: a metal washer and an elastomeric (rubber) gasket. This seemingly simple design provides a superior sealing solution for bolted connections and threaded fittings. The metal outer ring prevents over-compression and extrusion of the rubber part, while the inner rubber element creates a tight, leak-proof seal.

Originally known as “Dowty seals” after their originator, bonded seals have become a standard in the industry, available in various sizes and materials to suit a wide range of applications. The clever design of a bonded seal eliminates the need for complex machining of a groove to hold a separate O-ring, simplifying assembly and reducing the risk of leaks. We are the best Bonded Seals Provider.

Why Choose Puja Fluid Seals Pvt. Ltd

- Decades of Expertise and Experience: With over of experience in the sealing industry, Puja Fluid Seals brings a wealth of knowledge to the table. Their team is comprised of highly qualified and experienced professionals who understand the intricate needs of various industrial applications. This long-standing presence in the market is a testament to their reliability and commitment to quality.

- Comprehensive Product Range: Puja Fluid Seals isn’t just a bonded seals supplier; they are a one-stop-shop for a complete range of industrial rubber products. From O-rings and hydraulic seals to pneumatic seals and rubber bellows, they offer a vast inventory to meet diverse customer needs. Their extensive product line means you can source all your sealing requirements from a single, trusted provider, simplifying your procurement process..

- Uncompromising Quality and Certifications: Quality is at the core of Puja Fluid Seals’ philosophy. The company is an and certified company. These certifications are not just badges; they reflect a rigorous commitment to maintaining the highest standards of quality assurance, from raw material selection to the final product. They also offer products that meet various international standards.

- Customer-Centric Approach: Puja Fluid Seals’ mission is centered on customer satisfaction. They don’t just supply products; they provide solutions. Their team offers technical support and guidance to help you select the most suitable sealing product for your specific application. Testimonials from long-term clients highlight their dedication to timely delivery, fair pricing, and a strong partnership approach.

- State-of-the-Art Manufacturing Capabilities: The company has a well-equipped manufacturing unit in Pune, allowing them to control the entire production process and ensure consistent quality. They have modern machinery and a fully-equipped tool room for manufacturing high-quality dies and molds, which are essential for producing precision-engineered seals.

- Customer-Centric Approach: The company’s vision is to provide cost-effective, customized solutions with unmatched support and service. They have a reputation for on-time delivery and a strong track record of low rejection rates. Testimonials from long-standing clients highlight their reliability, friendly service, and the consistency of their high-quality products.

- Local Presence, Global Standards: Being located in Pune, Puja Fluid Seals Pvt. Ltd. is well-positioned to serve the industrial belt of the region with speed and efficiency. Their strong supply chain and logistical capabilities ensure that customers receive their orders promptly. At the same time, their commitment to international standards and quality means they can compete with the best in the world.

Applications of Bonded Seal

- Hydraulic and Pneumatic Systems: This is arguably the most common application. In high-pressure hydraulic lines and pneumatic connections, bonded seals ensure that there are no leaks of hydraulic fluid or compressed air, which is essential for the efficiency and safety of the system.

- Automotive Industry: From engines and transmissions to brake systems and fuel lines, bonded seals are used in numerous automotive applications to prevent fluid leaks and protect critical components from contaminants.

- Machinery and Manufacturing: Industrial machinery, including gearboxes, pumps, and valves, relies on bonded seals to maintain the integrity of their internal systems and prevent lubrication loss.

- Earthmoving and Construction Equipment: Heavy-duty machinery like excavators and bulldozers operate under immense pressure and in harsh conditions. Bonded seals provide the durable, leak-proof performance required for these demanding applications.

- Aerospace and Defense: With strict requirements for safety and performance, the aerospace and defense sectors use bonded seals in a variety of systems where reliability is non-negotiable.

- Chemical and Pharmaceutical Industries: For handling aggressive chemicals and other sensitive media, bonded seals made from specific materials like Viton or EPDM are used to ensure containment and prevent contamination.

- Agricultural Machinery: Tractors and other farm equipment operate in harsh conditions. Bonded seals are used in hydraulic systems, gearboxes, and other components to keep dirt and moisture out while preventing lubricant leaks.

- Construction and Earthmoving Equipment: Heavy machinery like excavators, bulldozers, and cranes rely on powerful hydraulic systems. Bonded seals are crucial for ensuring the integrity of these systems, as any leak could lead to a loss of power and a safety hazard.

- General Engineering: In countless other applications, from machine tools to industrial pumps and pipelines, bonded seals provide a robust and durable sealing solution.

Specifications Table of Bonded Seals

| Specification | Details |

|---|---|

| Material | Bonded Seals |

| Elastomer Material | NBR, Viton, EPDM, Silicone |

| Pressure Rating | Up to 1500 Bar |

| Temperature Range | -30°C to +200°C (Depending on elastomer) |

| Available Sizes | M5 to M100 and custom sizes |

| Hardness | 70 – 90 Shore A |

| Coating | Zinc / Phosphate / Uncoated |

| Tolerance | As per DIN 3869 / BS 1806 Standards |

Advantages of Bonded Seals

- Quality and Durability: A trusted supplier will use high-quality materials and adhere to stringent manufacturing standards. This ensures that their bonded seals offer superior performance, durability, and a longer service life, reducing the need for frequent replacements.

- Technical Expertise: A good supplier has in-depth knowledge of fluid sealing technology. They can help you select the most suitable bonded seal for your specific application, considering factors like pressure, temperature, chemical compatibility, and thread type. They can also offer customized solutions if your needs are unique.

- Wide Product Range: A comprehensive product catalog means you can find all your sealing solutions from a single source. This saves time and effort, simplifying your procurement process. A wide range of sizes, materials (like Nitrile, Viton, EPDM and designs like self-centralizing is a sign of a capable supplier.

- Competitive Pricing and Timely Delivery: While quality should always be the priority, competitive pricing is a significant factor. A reliable supplier will offer fair prices and, more importantly, ensure timely delivery of your orders to prevent costly downtime in your operations.

- Certifications and Standards: Look for suppliers who are certified to international quality standards like This indicates a commitment to quality management and continuous improvement, giving you confidence in their products and processes.

- Easy to Install: Bonded seals are incredibly easy to install, which saves time and reduces the risk of incorrect assembly. Their self-contained design means there’s no need for complicated grooves or special tools, simplifying the entire process.

- Reusabl:Depending on the application and the material, bonded seals can often be reused after disassembly. This can lead to cost savings and reduced waste in certain situations.

- Versatility: Bonded seals are available in a wide range of sizes, materials, and configurations to suit different applications and operating conditions. You can find them with different metals like mild steel or stainless steel and various elastomers such as Nitrile to handle specific fluids and temperatures.

Types of Bonded Seals

1. Standard Bonded Seals (Dowty Seals)

- These are the most common type of bonded seals, consisting of a metal ring bonded to an elastomer insert. They are designed for use with BS, ISO, or DIN standard fittings.

Applications: General hydraulic and pneumatic sealing.

2. Self-Centering Bonded Seals

- Also known as “centering” seals, these come with an extended metal ring to help the seal stay centered during installation.

Advantages:

- Easy installation

- Reduced risk of misalignment

- Improved sealing

Used in: High-pressure hydraulic and pneumatic systems.

3. Pressure-Activated Bonded Seals

- These bonded seals are engineered with a special elastomer that expands slightly under pressure, offering enhanced sealing performance in dynamic environments.

Ideal for: Critical high-pressure applications.

4. Fluorocarbon (Viton) Bonded Seals

- For applications involving high temperatures or aggressive chemicals, we offer bonded seals with Viton elastomer. They are highly resistant to heat, oils, and fuels.

Use Case: Automotive, aerospace, and petrochemical applications.

5. EPDM Bonded Seals

- EPDM rubber is known for excellent weather resistance and resistance to hot water and steam.

Use Case: Plumbing, water treatment, solar systems.

6. Customized Bonded Seals

- Have a unique requirement? At Puja Fluid Seals Pvt. Ltd., we manufacture customized bonded seals based on your specifications size, shape, material, and operating pressure.

Conclusion

Bonded seals may be small in size, but their impact on industrial operations is immense. They are a critical component for ensuring the safety, efficiency, and longevity of machinery in various sectors. For businesses in Pune, selecting the right bonded seals supplier is a decision that directly affects the quality and reliability of their products. We are the best Best Bonded Seals Supplier.

Puja Fluid Seals Pvt. Ltd. is more than just a supplier; we are a partner committed to your success. Our dedication to quality, extensive product range, technical expertise, and customer-focused service make us the ideal choice for all your bonded seal requirements. By choosing a reliable and experienced partner like us, you can be confident that your connections are secure, your operations are efficient, and your products are built to last.